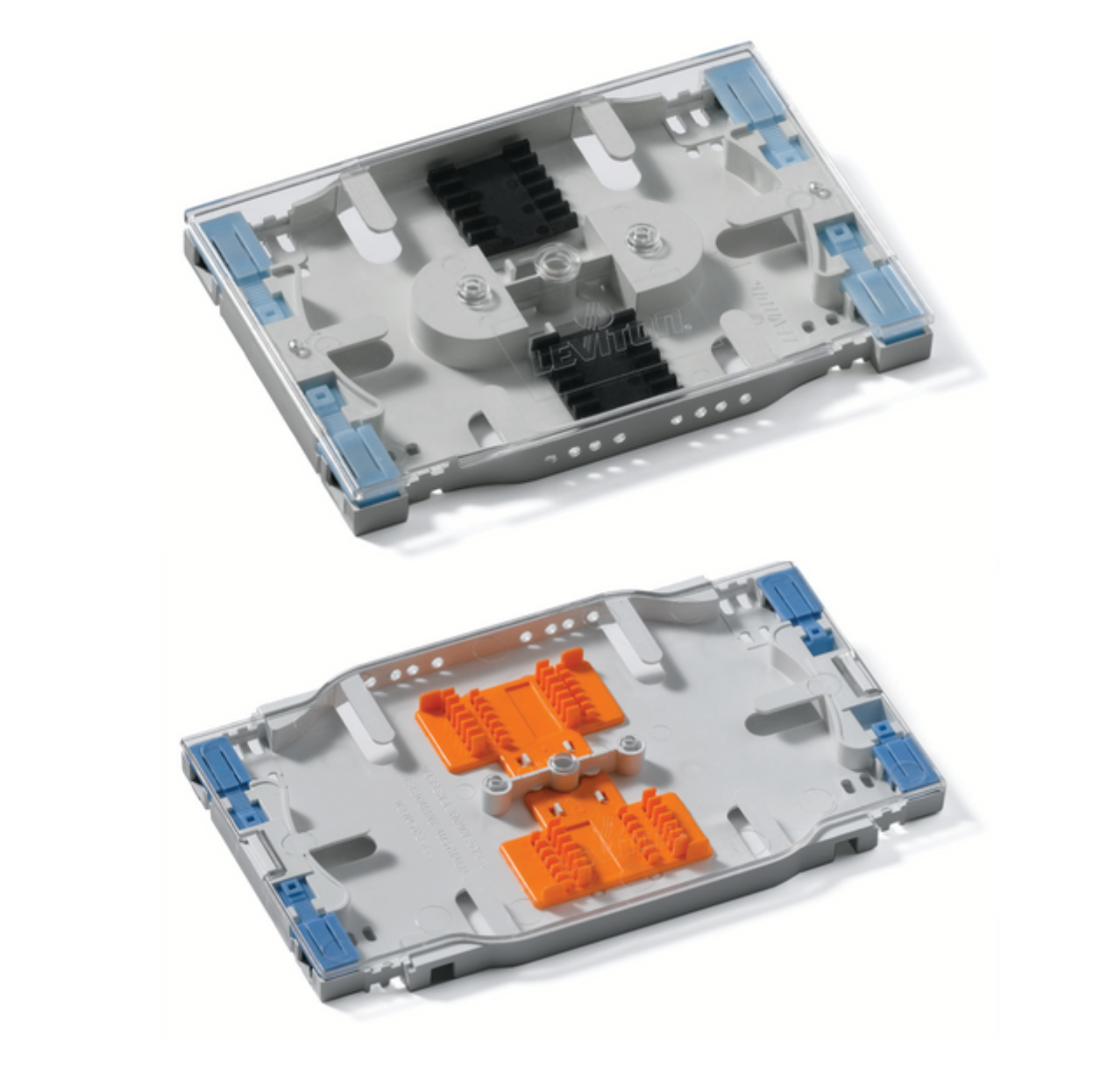

Leviton injection‑molded splice trays are available in 12‑fiber mini and 24‑fiber high‑density versions for use inside fiber enclosures. Trays provide slack management and protection for heat‑shrink fusion splices, include clear removable covers for inspection, use ratchet‑action foam‑padded clamps to secure incoming fiber, and accept standard 40 mm or 60 mm heat‑shrink splice sleeves.

Features and Benefits

- Four ratchet‑action clamps with foam rubber padding to minimize crush of loose tube or tight buffer fiber — secures incoming fiber while protecting it.

- Clear removable cover allows viewing and inspection of tray contents without cover removal — simplifies visual checks.

- Multiple tie‑down holes for securing incoming fiber — improves slack management.

- Accepts up to 12 or 24 heat‑shrink‑style fusion spliced fibers — supports common splice capacities.

- Splice sleeves included and accommodates 40 mm or 60 mm standard heat‑shrink sleeves — ready for splice protection.

- Durable injection‑molded G.E. Noryl E190 material, UL94 V‑0 rated — flame resistance and durability.

- 12‑fiber mini trays installable in all Leviton NID enclosures; 12‑ and 24‑fiber trays installable in Leviton SDX — broad enclosure compatibility.

Mechanical / Other Specifications

- Material: G.E. Noryl E190, UL94 V‑0 rated.

- Fiber supported: 250 µm or 900 µm.

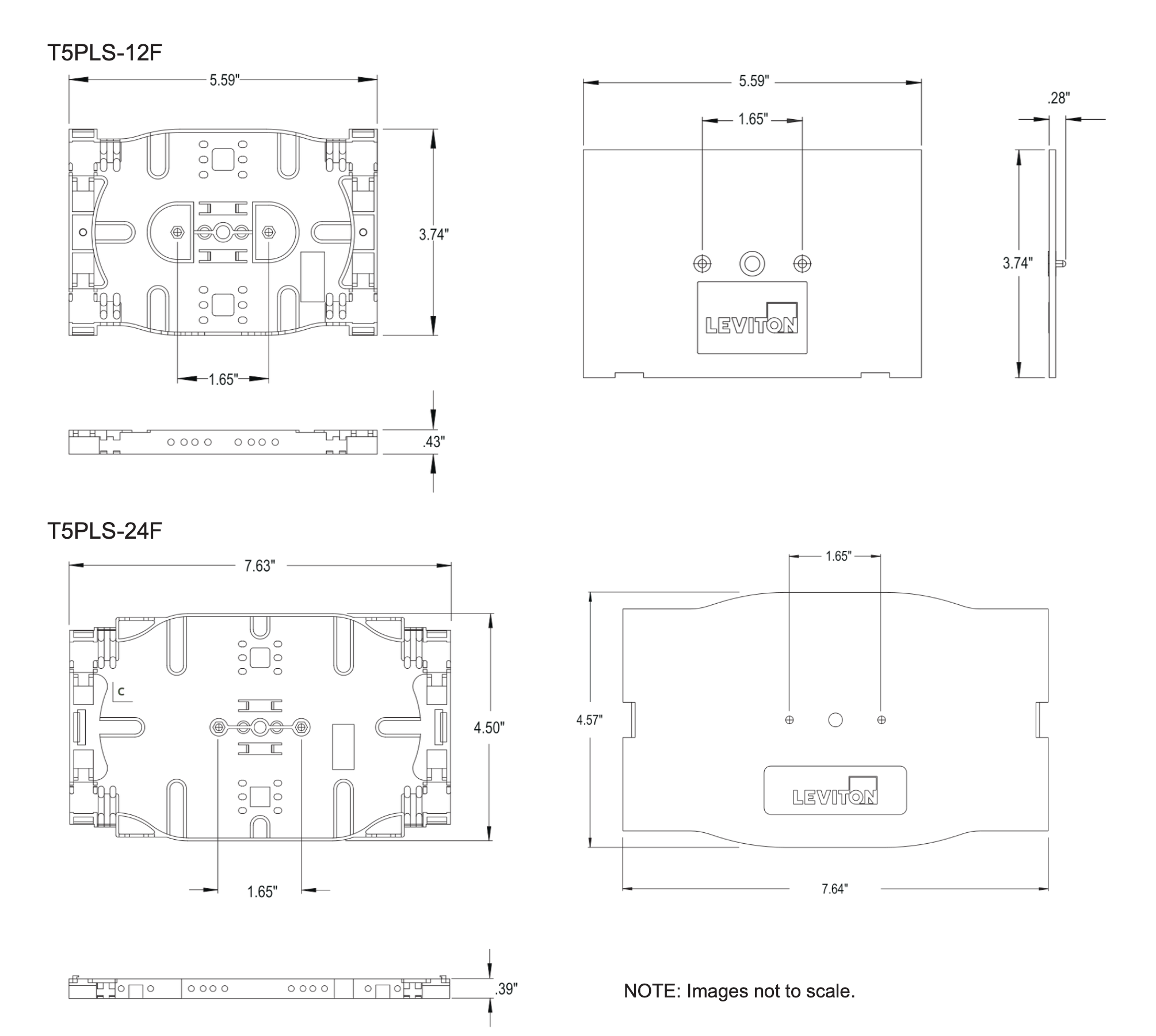

- Dimensions (illustrated approximations in PDF): T5PLS‑12F ≈ 5.59″ × 3.74″ × 1.65″; T5PLS‑24F ≈ 7.63″ × 4.50″ × 1.65″.

- Mounting: center hole for mounting; mounting hardware sold separately (SPLMT‑HKT).